In a more unpredictable world that threatens to disrupt global supply chains, we need access to safe and reliable streams of raw materials. Keeping materials and products in circulation for as long as possible makes our value chains more resilient and reduces both waste and emissions. When products have been put to good use and eventually reach their end-of-life, we need to ensure they are recycled and turned into new products.

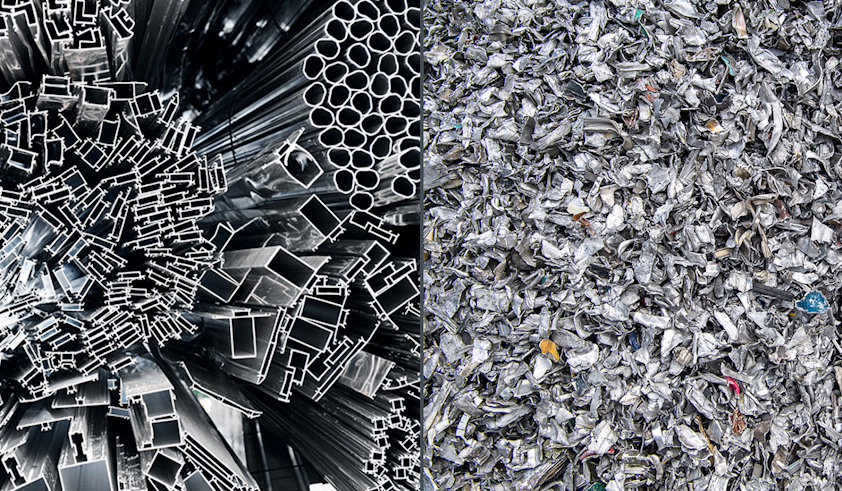

Theoretically, most things can be recycled, but some materials are better suited for recycling than others. Aluminium is lightweight, strong, corrosion-resistant, and infinitely recyclable without loss of the qualities that make it an ideal material for various uses and crucial for the green transition.

In addition, recycling aluminium requires only five percent of the energy needed to produce primary aluminium in a smelter. Aluminium scrap can safely be called energy in solid form.

In other words, keeping aluminium scrap in the loop is key to the circular and low-carbon economy.

Learn more about aluminium recycling and our operations in the sections below.

Increasing the share of recycled materials is an effective way to lower a product’s carbon footprint. Many companies turn to recycled aluminium in their efforts to decarbonize their value chain and achieve sustainability goals. However, not all recycled aluminium is equal.

To truly understand the carbon footprint of recycled aluminium, you need to know what kind of scrap is used in the recycling process. The ISO 14021 standard defines recycled content being made with post-consumer scrap and pre-consumer scrap respectively.

When we recycle aluminium from beverage cans, used windows, car parts or any other consumer product, the material starts a new life. Since the carbon emissions have already been accounted for during first time production, the carbon footprint of the recycled scrap is very low and mostly attributed to emissions from the remelting process. We refer to previously used aluminium as post-consumer scrap.

Aluminium scrap originating from production processes is different. This type of scrap originates from various stages of manufacturing before the material reaches the end consumer. It is typically clean, uncontaminated and highly recyclable, but it has not yet completed its life cycle and therefore carries the carbon footprint of the original material. We refer to this aluminium as pre-consumer scrap.

The recycling of pre-consumer scrap is a natural and necessary part of the aluminium value chain but does not neutralize the embedded carbon footprint. The recycling of post-consumer scrap, on the other hand, is the fastest way to achieve a low carbon footprint and prevents valuable materials from going to waste.

Still, large amounts of this valuable material are disposed of rather than being collected, sorted, and recycled. To address this, we are continuously exploring new possibilities both to source scrap and develop advanced sorting technologies to allow an increased amount of more challenging aluminium scrap to be sorted, repurposed, and given a new life.

The world has come to a point where it matters more than ever how and where materials are produced. Consumer patterns are affected by concerns over sustainability and ethical consumption. In combination with regulatory demand, growing consumer awareness can accelerate the circular economy by creating a pull for more sustainable and responsibly sourced materials.

Overstating the environmental performance or labeling products as “green” or “sustainable” without proper documentation is called greenwashing. To avoid this, we need more reliable and transparent information about where products come from and how they are produced.

With the naked eye, you cannot tell from the appearance of aluminium whether it is primary or secondary material, or if it’s made from pre- or post-consumer scrap. However, it means that the material’s footprint can vary greatly. We believe our customers should know not only the percentage of recycled content, but the actual footprint of recycled aluminium, which in turn will make it possible to define the footprint of the end product.

This is why we offer certified low-carbon and recycled aluminium that comes with a documented carbon footprint and assurances of safe and responsible production, designed to help customers reach their sustainability goals and gain the trust of climate-conscious consumers.

Our range of premium recycled aluminium, Hydro CIRCAL, is based on minimum 75 percent post-consumer scrap. It is delivered with an Environmental Product Declaration and verification statement from independent risk management and quality assurance company DNV. The production and raw materials can be traced on an individual batch level.

Considering aluminium’s infinite recyclability, it makes sense to design aluminium products in ways that make them easy to disassemble and recycle at the end of their life cycle. Up to two-thirds of a product's environmental footprint is decided in the design phase. In other words, engineers and product designers have great influence on a product’s sustainability through their material choices and design strategies.

Hydro EcoDesign is a design approach that focuses on creating aluminium products with increased functionality and reduced environmental footprint. It emphasizes the importance of selecting recyclable materials early in the design phase to create durable and resource-efficient products.

When engineers and designers familiarize themselves with the EcoDesign principles, they can help accelerate the circular economy by offering consumers greener and more sustainable choices.

When using a high proportion of recycled content in aluminium, the main challenge is how to meet the specific alloy requirements of the end product. This is possible only by putting together a very precise mixture of scrap qualities, which in turn requires advanced sorting, shredding, and melting technologies.

Increasing the share of recycled content in end products requires further innovation. That is why technical collaboration, alloy research and development of new applications are included in the scope of our strategic partnerships with both leading automotive customers such as Mercedes-Benz and Porsche as well as a niche customer like the iconic British folding bicycle company Brompton.

Brompton’s introduction of wheel rims made from 100 post-consumer aluminium scrap is the first application in a consumer product of Hydro’s CIRCAL 100R with a carbon footprint of less than 0.5 kg CO2e per kg aluminium.

Our recycling operations today consist of 34 plant facilities in Europe, North America and South America for our Aluminium Metal and Extrusions business areas, with a combined annual capacity of approximately 2.5 million tonnes. We recycled 451,000 tonnes of post-consumer scrap in 2024. The ambition to grow in recycling is a key element in Hydro’s 2030 strategy.

Recent additions include the greenfield plant built in Cassopolis, Michigan, and the new plant at Székesfehérvár, Hungary. Further recycling capacity will be coming on stream no later than 2026, including a new recycling plant in Torija, Spain with specialty capabilities and an annual capacity of 120,000 tonnes.

Our sorting plant in Dormagen, Germany also serves as a research and development facility for our HySort technology using advanced laser induced breakdown spectroscopy (LIBS), which allows us to dig deeper into the scrap pile and recycle more challenging scrap types. This is scrap that historically might have gone into secondary castings or even left the loop altogether, ending up in landfills.

In addition to Dormagen, HySort is currently operational at the Alusort sorting hub in Grandville, Michigan and at Nowa Sól, Poland. The technology will also be used at the new sorting facility to be built at Hydro Wrexham, UK.

Recycling technology has also been introduced at Hydro’s Årdal and Høyanger primary plants in Norway, where recycled aluminium is mixed with primary aluminium directly in the casthouses. Depending on the share of post-consumer scrap, Hydro REDUXA low-carbon aluminium can be delivered with a documented carbon footprint of below 4 kg CO2e per kg aluminium.

Remelting aluminium into new products is an energy intensive process where burners using fossil fuel are traditionally used to achieve the required high temperatures. As part of our technology roadmap to net-zero, we have research and development underway at several locations with the aim of switching from natural gas to renewable energy sources in casthouse furnaces.

In the Høyanger recycling facility in Norway, we are replacing natural gas with green hydrogen in one of the furnaces. The pilot project builds on the experience from the world’s first industrial scale test of green hydrogen in aluminium recycling at Hydro Navarra, Spain in June 2023.

At the Sunndal primary plant, we have replaced 70 percent of the natural gas consumption with locally sourced biomethane. Meanwhile, in the site’s R&D facilities, we are exploring the use of plasma technology to enable electrification of casthouse furnaces. Both initiatives are part of our ongoing effort to unlock the potential of climate-neutral energy sources in remelting operations.

Updated: October 3, 2025