Hydro Rackwitz: 100 years young and more to give

Construction, destruction, reconstruction. World war, cold war and peace. Hydro’s sister aluminium plants in Rackwitz have essentially seen it all since 1925, and the 100 year old production site is not done yet.

Since the establishment of a small aluminium research hub in 1925, the Saxonian community of Rackwitz, just north of Leipzig, has been closely tied to aluminium. Today, the site is home to two Hydro operations, an extrusion plant, and an aluminium recycler and casthouse. Managing directors Josephine Noack and Thomas Stürzebecher reflect on a century of change and resilience while looking ahead.

Navigating changing tides

“In many ways you could say Rackwitz mirrors Germany’s contemporary history. For a century, we have been following the changing tides. Our story is one of dramatic ups and downs, but it’s also a tale of resilience and the ability to adapt to a changing landscape,” says Thomas Stürzebecher, plant manager of the Rackwitz casthouse, who himself is celebrating an anniversary this year.

For 25 years, Thomas has been the plant manager and overseen its development from remelting operation to a highly specialized aluminium recycling plant with full automotive capabilities.

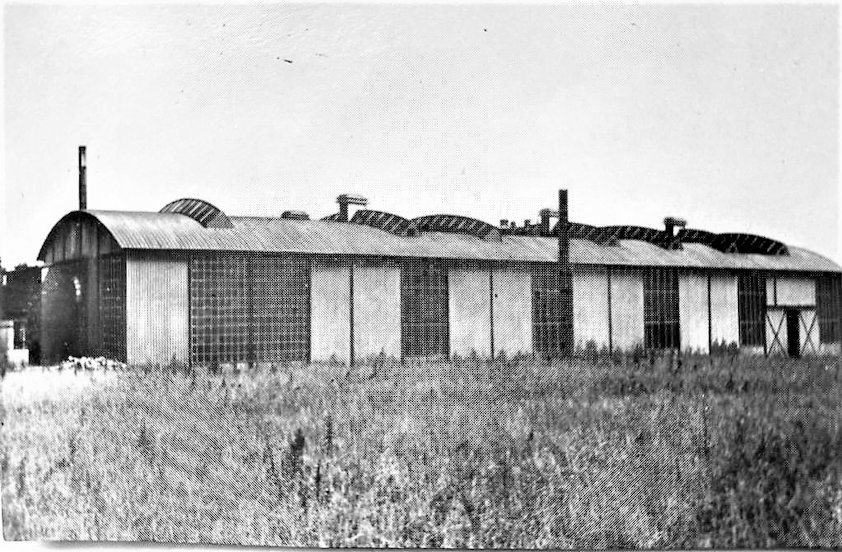

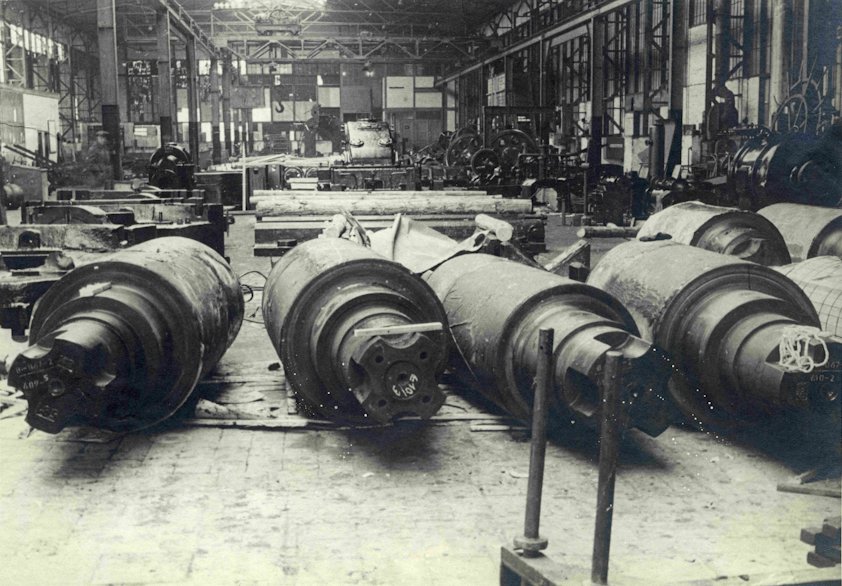

Rackwitz looks back at a rich and dramatic history. From the humble beginnings in the interwar period, Rackwitz later grew into a key remelting and extrusion plant and soon came to play a role feeding the armaments industry. After World War II, all the production equipment that was left intact after allied bombing was dismantled, then shipped to the Soviet Union as war reparations.

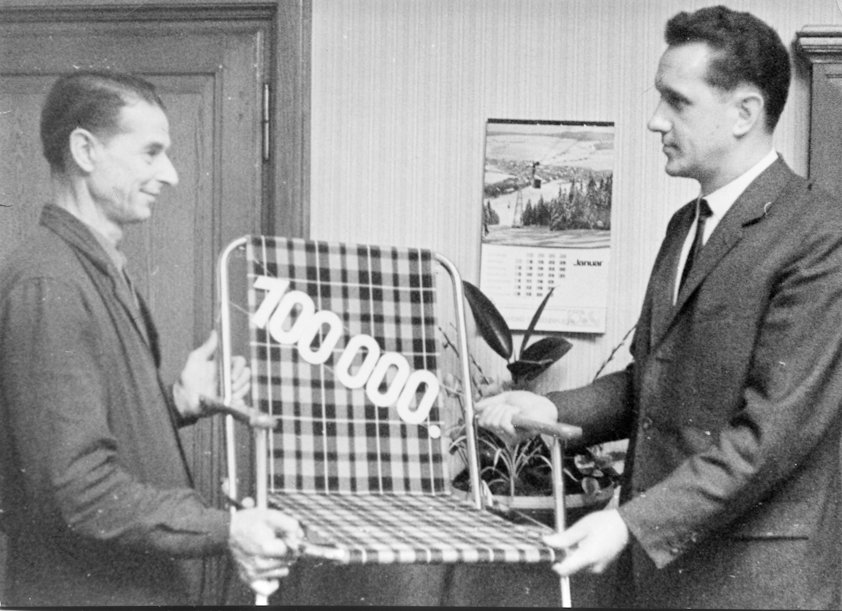

“After the war, the aluminium works in Rackwitz ended up behind the iron curtain. They were rebuilt and turned into a model socialist state enterprise, growing steadily until the fall of the Berlin Wall in 1989 brought another radical turn in history. Symbolically, 4500 tonnes of aluminium coins were sent to Rackwitz and melted down after the German Democratic Republic's (GDR) currency was abolished in 1990,” tells Thomas.

The core areas, casthouse and extrusions, were privatized in 1994. Hydro took over in 1997, at which time the workforce had shrunk from 2400 in the socialist peak to just 150. Since then, Rackwitz has grown back into a local community cornerstone.

In 2016, Josephine Noack, a trained mechanical engineer, came to work as quality manager at what is likely the world’s oldest operational aluminium extrusion site. Now managing director of Hydro Extrusion Rackwitz, she has felt at home since the day she arrived, immediately drawn by the site’s strong team spirit and welcoming atmosphere.

"What makes Rackwitz so special is not just its history and the advanced technology, but above all the spirit that prevails here. We are a team that can rely on each other. This family like culture is deeply rooted in our history, and it ensures we will remain strong in the future. It’s an environment where work and life go well together, and that motivates me every single day," says Josephine.

Today, the two plants together employ well over 300 people, offering jobs and career opportunities while serving hundreds of customers across Germany.

Pencil to paper research and modern manufacturing

Historically, the aluminium works in Rackwitz have been a major employer in the region, supporting thousands of families with stable jobs and career opportunities. During the GDR era, in addition to jobs, the site offered community infrastructure: medical services, education, childcare, sports clubs, and cultural life, effectively becoming a small town within a town.

“We still strive to be an integral part of the local community. We hold joint emergency exercises with the Rackwitz fire department, we are proud sponsors of the local sport clubs and the local summer festival, and donations regularly go out to local charitable associations. As a cornerstone business, we know that we are equally dependent on a thriving local community as a source for both services and recruitment base for dedicated employees,” says Josephine.

Investments in later years have increased capacity, expanded the product range, and created more jobs. In 2023, a third press went into operation at the extrusion plant, while the recycling plant opened a new casting line to serve the region’s automotive industry.

“The recycling and extrusion plants are separate entities within the Hydro group, yet we are inseparable through our common history and complementary operations. With the latest investments in state-of-the-art technology and equipment, we will continue to play an important role serving key European industries such as automotive manufacturing and building & construction. We are proud to contribute to the local and regional economy by spearheading advances in high tech aluminium casting and extrusion,” says Thomas.

Aluminium has strategic importance in Europe

The European Union has defined aluminium as a strategic material, key to the infrastructure makeover that Europe needs to boost competitiveness and strengthen preparedness in a shifting geopolitical landscape.

The demand for low-carbon and recycled aluminium is growing along with the need to bring down energy prices and accelerate the transition to renewable energy. Europe needs to become more self-sufficient and less dependent on external sources for both energy and critical raw materials. Keeping aluminium scrap in the loop instead of exporting it to other markets is key to building a more circular and competitive economy in Europe.

“Within automotive, one of our core segments, we see a slowdown in the growth of electric car sales. But the electrification of the transport sector is happening, and recycled aluminium is a key enabler. Rackwitz is ideally located to provide the automotive industry with a material that they need,” says Thomas.

Likewise, electrification and the roll out of renewable energy installations continue at a rapid pace. For infrastructure, buildings and automotive, the need for aluminium is growing, and the demand for low-carbon, recycled material is expected to grow the most.

"A site like Rackwitz comes with great responsibility, toward the employees, the region and our customers. Carrying this responsibility is not a burden for me, but a matter of true conviction. We stand for quality, reliability and more sustainable perspectives. I’m proud to actively shape the future together with a dedicated team, not just for our company, but also for future generations. Being part of this development is something I consider a great privilege," says Josephine.

“We have an important job ahead of us as Europe is moving towards a more circular economy and mobilizing to strengthen its total preparedness. Rackwitz has a role to play as a stable and predictable provider of a critical raw material in a challenging time for Europe. If history has taught us anything, it’s that we are ready to take on the next 100 years,” Thomas concludes.

Facts about Hydro’s aluminium operations in Rackwitz

Hydro Extrusion Rackwitz is likely the oldest aluminium extrusion site in the world still in operation. It operates three aluminium extrusion lines and a fully automatic anodizing line with extensive possibilities for mechanical treatment. The plant employs over 200 people and has an annual capacity of 40,000 tonnes of extruded profiles, serving approximately 650 customers within the building and construction, transportation and general engineering market segments.

Both process scrap and post-consumer scrap are remelted next door at Hydro Aluminium Gießerei Rackwitz. The state-of-the-art aluminium recycling plant employs 90 people and has an annual capacity of 97,000 tonnes of extrusion ingot, destined for German and other European extruders, including Hydro Extrusion Rackwitz. In 2023, the plant began operating a new casting line with an additional annual capacity of 24,000 tonnes of HyForge forging stock for the automotive segment.